Fuel Hydrant System Design by Smart Jet Engineering

By - Admin

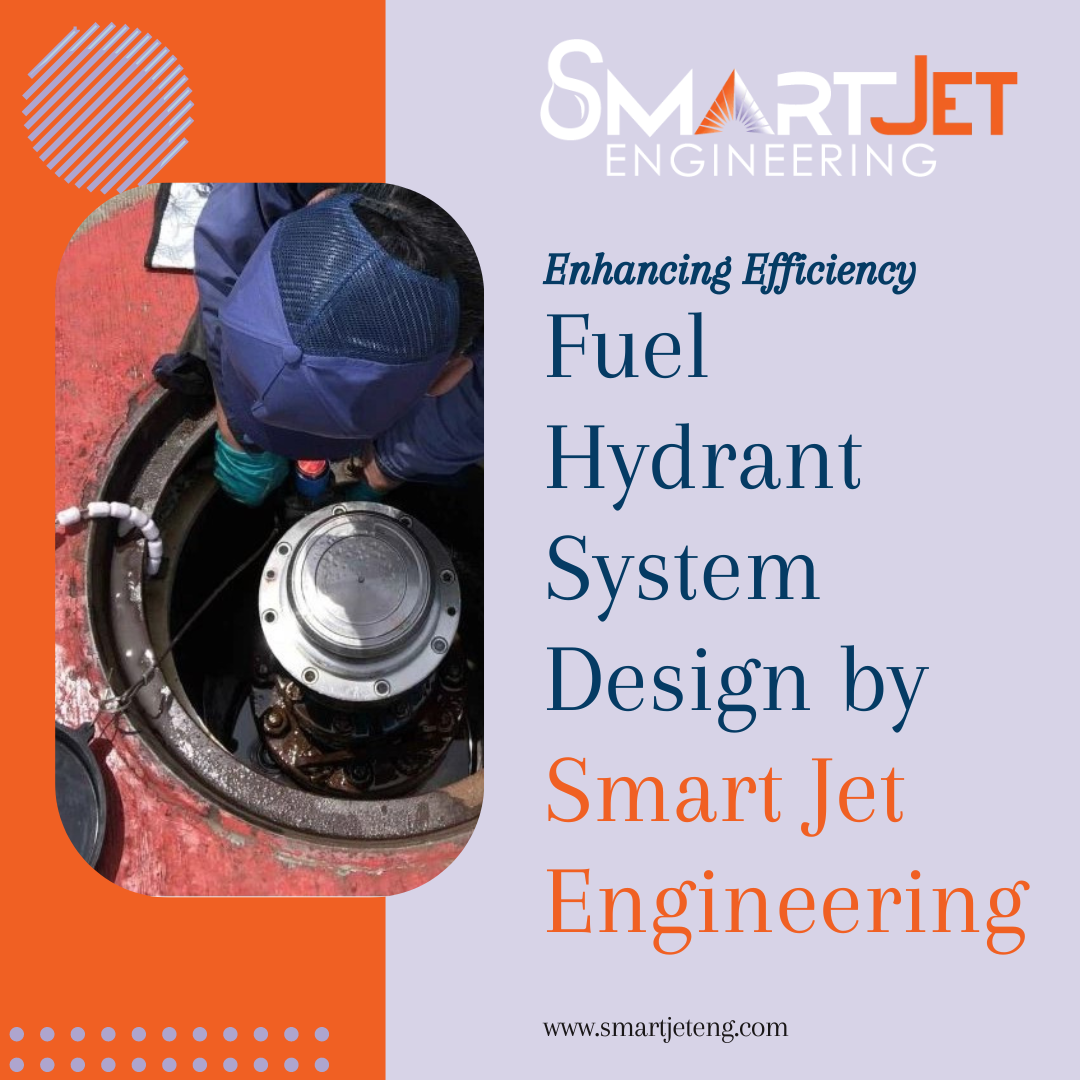

Enhancing Efficiency: Fuel Hydrant System Design by Smart Jet Engineering

Introduction

In the dynamic world of aviation, efficient fuel management is essential to ensure smooth operations and safety. As a leading provider of engineering solutions in Dubai, Smart Jet Engineering understands the significance of innovative fuel hydrant system design. In this article, we delve into the intricacies of fuel hydrant system design, highlighting its importance, components, and benefits for airports and aviation stakeholders.

Understanding Fuel Hydrant System Design

Fuel hydrant systems are integral components of airport infrastructure, facilitating the seamless transfer of aviation fuel from storage tanks to aircraft. These systems comprise a network of pipelines, hydrant pits, valves, and control mechanisms designed to deliver fuel safely and efficiently. Smart Jet Engineering specializes in designing customized fuel hydrant systems tailored to the unique requirements of each airport, optimizing fuel distribution processes and enhancing operational efficiency.

Key Components of Fuel Hydrant System Design

1. Pipeline Network

- Primary Conduit: The pipeline network forms the backbone of the fuel hydrant system, transporting fuel from storage facilities to hydrant pits located on the apron or taxiways.

- Material Selection: Smart Jet Engineering employs high-quality materials such as stainless steel or reinforced composite for pipeline construction, ensuring durability and corrosion resistance.

2. Hydrant Pits

- Fuel Dispensing Points: Hydrant pits serve as access points for fueling aircraft, equipped with fueling nozzles and control valves for efficient fuel delivery.

- Safety Features: Smart Jet Engineering integrates safety features such as emergency shut-off valves and pressure relief systems to mitigate risks associated with fuel handling.

3. Control Systems

- Automation and Monitoring: Advanced control systems enable remote operation and real-time monitoring of fuel distribution processes, optimizing efficiency and safety.

- Integrated Alarms: Smart Jet Engineering incorporates alarm systems to alert operators of any anomalies or potential hazards, ensuring prompt intervention and mitigation.

4. Filtration and Quality Control

- Filtration Mechanisms: Fuel hydrant systems are equipped with filtration units to remove contaminants and impurities, ensuring fuel quality and integrity.

- Compliance with Standards: Smart Jet Engineering adheres to international standards and regulatory requirements for fuel quality control, safeguarding aircraft engines and minimizing operational risks.

Benefits of Fuel Hydrant System Design

1. Operational Efficiency

- Streamlined Fueling Processes: Fuel hydrant systems eliminate the need for fuel trucks and manual refueling operations, reducing turnaround times and enhancing operational efficiency.

- Optimized Resource Allocation: By automating fuel distribution processes, airports can allocate manpower and resources more effectively, improving overall productivity.

2. Safety and Reliability

- Reduced Human Error: Automated control systems minimize the risk of human error during fueling operations, enhancing safety and reliability.

- Emergency Response Preparedness: Fuel hydrant systems are equipped with safety features and contingency measures to address emergencies promptly, ensuring minimal disruption to operations.

3. Environmental Sustainability

- Emission Reduction: By eliminating the use of fuel trucks and reducing fuel handling activities, fuel hydrant systems contribute to lower carbon emissions and environmental impact.

- Resource Conservation: Efficient fuel distribution minimizes fuel wastage and spillage, conserving resources and promoting sustainability in aviation operations.

Conclusion

Smart Jet Engineering's expertise in fuel hydrant system design is instrumental in advancing aviation infrastructure and fuel management practices. By leveraging innovative technologies and engineering solutions, airports can enhance operational efficiency, safety, and environmental sustainability. With a focus on customization, quality, and compliance, Smart Jet Engineering remains at the forefront of fuel hydrant system design, driving progress and excellence in the aviation industry.

FAQ’s

Q.1. What factors are considered in the design of a fuel hydrant system?

Fuel hydrant system design takes into account factors such as airport layout, traffic volume, aircraft types, and regulatory requirements to ensure optimal performance and safety.

Q.2. How does Smart Jet Engineering ensure compliance with regulatory standards in fuel hydrant system design?

Smart Jet Engineering conducts thorough assessments of regulatory requirements and industry standards, incorporating them into the design and implementation of fuel hydrant systems to ensure compliance.

Q.3. Can existing airports upgrade their fueling infrastructure with a fuel hydrant system?

Yes, Smart Jet Engineering offers retrofitting services to upgrade existing airports with fuel hydrant systems, enhancing their operational capabilities and efficiency.

Q.4. What maintenance procedures are involved in ensuring the reliability of a fuel hydrant system?

Regular inspection, testing, and maintenance of components such as pipelines, hydrant pits, and control systems are essential to ensure the reliability and integrity of a fuel hydrant system.

Q.5. How does the implementation of a fuel hydrant system contribute to cost savings for airports?

By reducing the need for fuel trucks, manual refueling operations, and associated labor costs, fuel hydrant systems offer significant cost savings for airports over the long term, offsetting initial investment expenses.

Related Blogs

Search

Popular Posts

The Importance of Ground Fuel Monitoring in Modern Aviation Operations

March 27, 2025

The Importance of Fuel Storage Tanks in Modern Aviation Operations

March 27, 2025

Why Testing and Commissioning is the Ultimate Step in Quality Control

January 29, 2025

Unlocking the Power of Flow Meters: The Critical Role of Calibration

January 29, 2025

Industrial Plant Maintenance and Servicing

March 22, 2025