Aircraft Refueling Equipment

By - Admin

Aircraft Refueling Equipment: Ensuring Safe and Efficient Fuel Management

Introduction

Welcome to Smart Jet Engineering! We are a premier aviation solutions provider based in Dubai, and today, we’ll explore the critical role of aircraft refuelling equipment in the aviation industry. This equipment is vital for maintaining efficient and safe fueling operations for aircraft. Let's dive into what this equipment entails and why it’s so essential.

What is Aircraft Refueling Equipment?

Aircraft refuelling equipment includes all the tools and machinery used to store, transport, and dispense aviation fuel to aircraft. These systems are designed to ensure that fueling operations are conducted safely, efficiently, and in compliance with industry standards.

Key Components of Aircraft Refueling Equipment

- Fuel Storage Tanks: Securely store large volumes of aviation fuel.

- Pumps: Transfer fuel from storage tanks to dispensing units.

- Filters: Remove impurities from the fuel to ensure quality.

- Hoses and Nozzles: Facilitate the transfer of fuel to the aircraft.

- Meters: Measure the amount of fuel dispensed accurately.

Types of Aircraft Refueling Equipment

Refueling Trucks

These mobile units are equipped with fuel tanks, pumps, hoses, and dispensing nozzles. They are used to transport fuel directly to aircraft, making them ideal for flexible and on-the-go fueling operations.

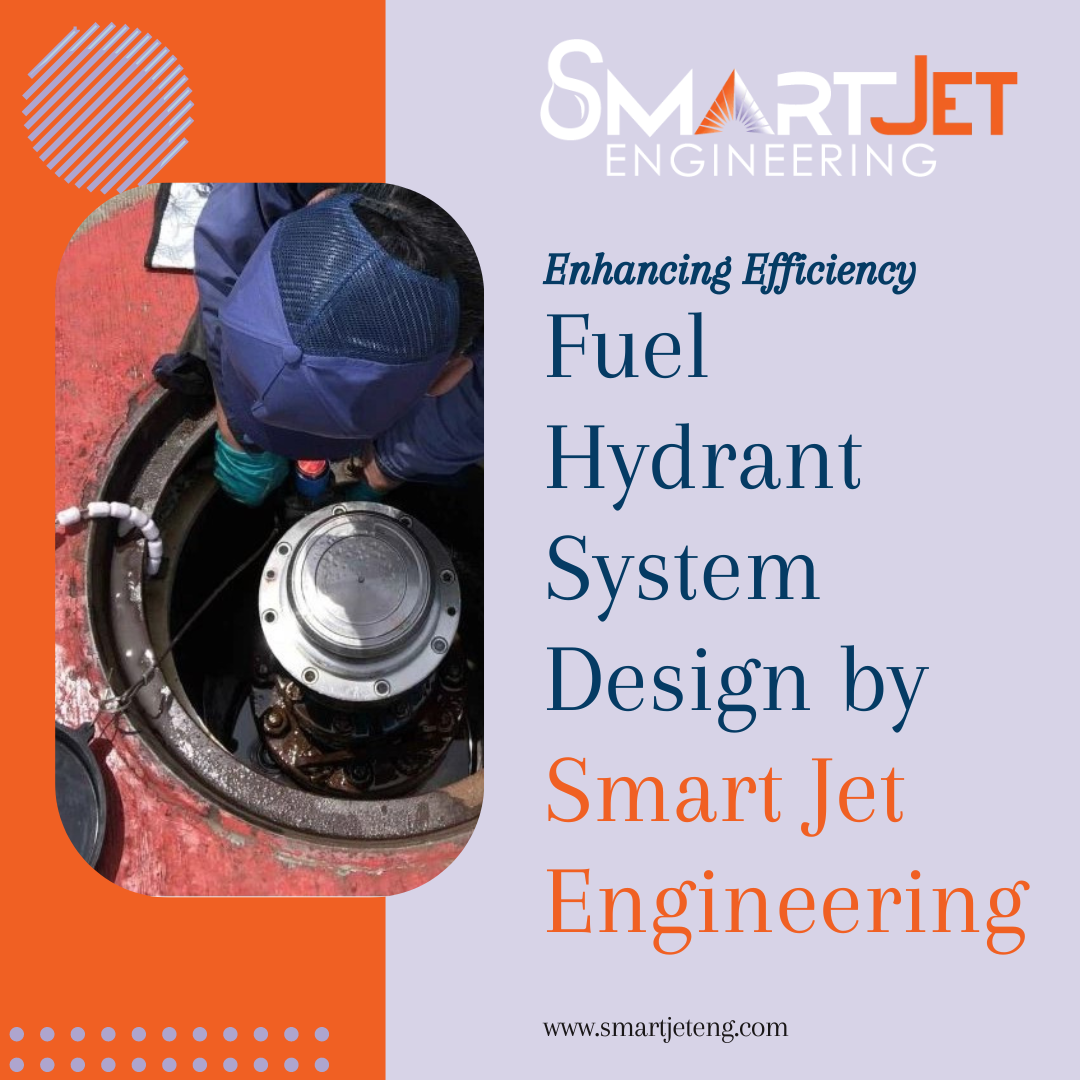

Hydrant Carts

Hydrant carts connect to underground fuel hydrant systems at airports. They are used to transfer fuel from the hydrant system to the aircraft, providing a more permanent and large-scale fueling solution.

Fuel Dispensing Units

These stationary units are installed at fixed locations, such as fueling stations at airports. They are designed for high-volume fuel dispensing and are equipped with advanced safety and monitoring features.

Benefits of Modern Aircraft Refueling Equipment

Efficiency and Speed

Modern refuelling equipment ensures quick and efficient fueling operations, reducing aircraft turnaround times and improving operational efficiency.

Safety Features

Advanced safety features, such as automatic shutoff valves, pressure control systems, and leak detection, help prevent accidents and ensure safe fueling operations.

Environmental Impact

Eco-friendly refuelling equipment helps minimize environmental impact by reducing emissions, preventing fuel spills, and promoting the use of sustainable fuels.

How Aircraft Refueling Equipment Works

Fuel Storage and Transportation

Fuel is stored in large, secure tanks and transported to the aircraft using refuelling trucks or hydrant systems. These tanks are designed to prevent contamination and leakage.

Fuel Dispensing Process

Fuel is pumped from storage tanks through hoses and nozzles to the aircraft. Advanced dispensing units include digital meters for accurate measurement and control systems to regulate the flow and pressure of the fuel.

Choosing the Right Aircraft Refueling Equipment

Assessing Your Needs

Evaluate your operational requirements, including the volume of fuel needed, the number of aircraft to be serviced, and the specific fueling conditions at your location.

Capacity and Compatibility

Choose equipment with the right capacity and compatibility with your existing infrastructure. Ensure that the equipment can handle your current and future fueling needs.

Compliance with Regulations

Ensure that your refuelling equipment complies with all relevant regulations and standards to guarantee safe and legal operations.

Maintenance and Care for Aircraft Refueling Equipment

Routine Inspections

Conduct regular inspections to detect and address any potential issues early. Check for leaks, wear, and proper functioning of all components.

Cleaning and Upkeep

Regular cleaning prevents contamination and maintains the equipment’s functionality. Use appropriate cleaning agents and techniques to ensure hygiene and safety.

Troubleshooting Common Issues

Be prepared to troubleshoot common problems such as pump failures, hose leaks, and meter inaccuracies. Having a maintenance manual and spare parts available can be very helpful.

Safety Protocols in Aircraft Refueling

Industry Safety Standards

Adhere to industry safety standards set by organizations such as the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO).

Emergency Response Procedures

Develop and implement comprehensive emergency response plans to handle potential incidents like fuel spills or fires. Train staff regularly on these procedures.

Aircraft Refueling Equipment vs. Traditional Refueling Methods

Comparative Analysis

Modern refuelling equipment offers numerous advantages over traditional methods, including greater efficiency, enhanced safety, and reduced environmental impact.

Advantages of Modern Equipment

- Precision: Advanced equipment ensures accurate fuel measurement and delivery.

- Safety: Built-in safety features minimize the risk of accidents.

- Efficiency: Automated systems streamline fueling operations, reducing downtime.

Technological Innovations in Aircraft Refueling Equipment

Automation and Smart Systems

The latest refuelling equipment incorporates automation and smart technologies for real-time monitoring, remote control, and data analytics, enhancing operational efficiency and safety.

Eco-Friendly Developments

Innovations such as the use of biofuels, emission control systems, and spill prevention technologies contribute to a more sustainable aviation industry.

Case Study: Successful Implementation of Aircraft Refueling Equipment

Real-world Example

A major international airport recently upgraded its refuelling equipment, resulting in a 25% increase in fueling efficiency and a significant reduction in fuel-related incidents.

Key Takeaways

This case study highlights the importance of advanced refuelling equipment in improving operational efficiency, safety, and environmental sustainability.

Regulatory Compliance for Aircraft Refueling Equipment

International Standards

Compliance with international standards, such as those from IATA and ICAO, is essential for safe and efficient fueling operations.

Local Regulations in Dubai

In Dubai, aviation fuel systems must meet the General Civil Aviation Authority (GCAA) regulations, ensuring they are up to standard with local requirements.

Why Choose Smart Jet Engineering for Your Aircraft Refueling Equipment Needs

Our Expertise and Experience

At Smart Jet Engineering, we bring unparalleled expertise and a commitment to excellence. Our team is dedicated to providing top-of-the-line aircraft refuelling equipment tailored to your specific needs.

Customer Testimonials

Our clients trust us for our high-quality products, exceptional service, and unwavering reliability. Hear from satisfied customers who have benefited from our solutions.

Future Trends in Aircraft Refueling

Predictions and Insights

The future of aircraft refuelling includes greater automation, enhanced safety measures, and increased use of sustainable fuels. Staying ahead of these trends is essential for operational success.

Conclusion

Aircraft refuelling equipment is vital to the aviation industry, offering efficiency, safety, and environmental benefits. Whether you're managing a large airport or a private fleet, the right refuelling equipment can make a significant difference.

FAQs

Q.1 What is the lifespan of aircraft refuelling equipment?

The lifespan of aircraft refuelling equipment typically ranges from 15 to 25 years, depending on usage and maintenance.

Q.2 How often should aircraft refuelling equipment be inspected?

Regular inspections should be carried out monthly, with comprehensive checks annually.

Q.3 Can aircraft refuelling equipment be customized?

Yes, aircraft refuelling equipment can be tailored to meet specific operational requirements and capacities.

Q.4 What safety features are included in aircraft refuelling equipment?

Key safety features include automatic shutoff valves, pressure control systems, leak detection, and fire suppression systems.

Q.5 How do I ensure my aircraft refuelling equipment is compliant with regulations?

Ensure compliance by following international and local standards, conducting regular audits, and staying updated with regulatory changes.

Search

Popular Posts

Fuel Management Systems: Smarter Control for Modern Fuel Operations

December 10, 2025

Pipe Support Engineering: Ensuring Strength, Stability, and Long-Term Reliability

December 10, 2025

Mobile Fuel Equipment: The Future of Safe and Efficient On-Site Refueling

December 10, 2025

Fuel Dispensing Systems: Reliable Solutions for Safe and Efficient Fuel Delivery

December 10, 2025

Tanker Refurbishment and Modification Services in UAE | Smart Jet Engineering

November 29, 2025